Harness key raw material understanding

1. Wire cognition

Wire defines a wire product used to transmit electrical energy, information and achieve electromagnetic energy conversion. Wire and cable development history ★ In 1744 wire was born, wire and cable into practical, has been more than 250 years of history. 1938 developed PVC, PE, wire and cable into the era of a large number of plastic applications. ★ The emergence of optical fiber in the 1970s, the recent progress of superconductivity and nanotechnology, more wire and cable production, development, application into a new stage and field.

Power cables, also known as force cables, are used for transmission cables; Underground laying is often done. Overhead wire (bare wire), also known as bare wire, is often used for long-distance transmission of electrical energy; Overhead laying is often done. Communication cables are used to transmit electrical signals; It is often laid underground or overhead. Enamelled wire (winding wire), also known as winding wire, is used in motor winding to convert electrical energy into mechanical energy. Wire for electronic and electrical equipment is used as installation wire for electronic and electrical equipment, also known as electronic wire. Optical fiber cable is used to transmit optical signals, because of its low attenuation performance, commonly used as a long-distance communication trunk.

Various standards for wire and cable International Standards International Electrotechnical Commission Standards IEC.

American Underwriters Laboratory standard UL (our commonly used wire, the following is mainly for UL wire is introduced).

Us military standard MIL-C-17G. Japanese industrial standards JISC,JISK, etc.

German industrial standard DIN.

British National Standard BS.

IEEE Standards for Electrical and Electronics Engineers.

Domestic standard National standard GB/TXXXX-XXXX,GBXXXX-XXXX.

Communication industry standard YD/TXXXX-XXXX.

Machinery industry standard JBXXXX-XXXX.

Electronics industry standard SJ/TXXXX-XXXX

2-1-4, wire commonly used conductor

1, copper foil wire A copper foil strip (flattened by copper wire) wrapped on the polyester fiber into a strand, and then four strands of regular twisted. Copper foil wire elasticity, softness and bending strength is good, because containing fiber core, easy to absorb moisture and oxidation black. It is mainly used as a conductor (also known as coaxial line) for telephone curves and game lines.

2, bare copper wire Bare copper wire has high conductivity, but it is easy to oxidize at high temperatures. There are single (or solid) bare copper wire and stranded bare copper wire. The purpose of stranding is to keep the conductor soft, (also known as AD wire)

3, tinned copper wire with hot plating or electroplating the metal tin is plated on the surface of the copper conductor to prevent copper corrosion/discoloration, and make the conductor easier to weld. Divided into single (or solid) tinned copper wire and stranded. The purpose of stranding is to keep the conductor soft (also known as TD wire).

4, bare stranded copper plated wire is mainly used for electronic wire, on the one hand, easy to solder, on the other hand because the conductor is hard, not easy to bend, easy to plug into the printed circuit board (also known as TC wire).

5, stranded copper wire is mainly used for electronic wire, the performance is the same as bare stranded copper wire, tin layer adhesion is better than bare stranded copper wire (also known as TS wire).

Basic determination method: The surface is relatively smooth, when burning, the flame is yellow and blue, dripping, and there is a slight candle smell.

PP polypropylene appearance is a white waxy solid, more transparent, non-toxic, small water absorption, only 0.03-0.04%, flammable. With a specific gravity of 0.91, it is one of the smallest plastics in common use. Mainly used for core wire insulation. Basic determination method: The surface is relatively smooth, compared with PE, harder, when burning, the flame is yellow and blue, dripping, there is a smell, and only after a slight candle smell.

XLPE/XL-PVC thermosetting material, mainly used as insulation, XLPE maximum temperature grade up to 150 degrees Basic identification method: cut a section of wire, remove the conductor, start burning with fire from the middle, and then force the line to break, the section is very round.

PU has good physical and chemical properties, and is often used in the sheath of connecting wires and spring wires of construction machinery and other equipment. Basic identification method: magnetic, elastic, burning expansion and mixed with dripping.

TPE/PO (thermoplastic elastomer) low smoke halogen-free fuel.

This article is compiled and published by "Yishen Electronics", if you need to reprint, please indicate the source and source, original address:https://www.yixiandianzi.com/news/164.html

Dongguan Yixian Electronic Technology Co., Ltd.

Tel: +86-0769-82822709

Phone: +86-18819098350/18819095853

E-mail: [email protected]/[email protected]

Address: 301 Room 2 Block No.39 Chuangye Road Mulun Village Changping Town Dongguan City Guangdong

From the point of view of the use of the terminal, the function that should be achieved is that the ...

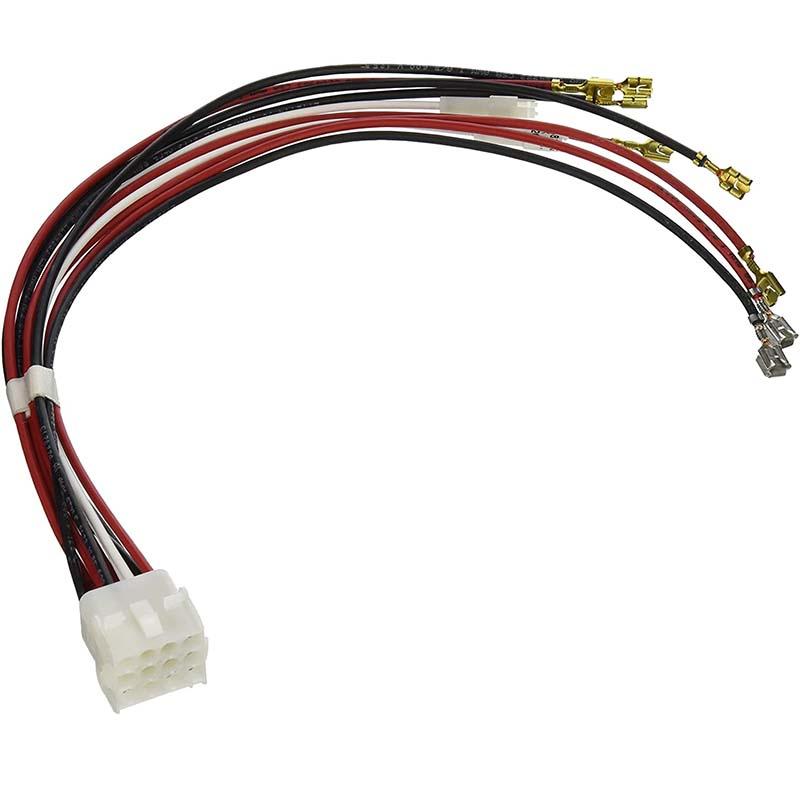

Focus on a variety of custom wire harnesses, electronic wires, terminal wires, wire harnesses, cable...

What are the conceptual differences between terminals, connectors and connectors?

When electronic custom wire harness wire manufacturers produce environmentally friendly electronic w...

The principles that should be considered in the design process of automobile wiring harness

What do you think is the reason for the good quality of wiring harness?

Connectors and terminals

3C Home appliance wiring harness

Industrial equipment wiring harness

Flexible Flat Cable

3C Home appliance wiring harness

3C Home appliance wiring harness

3C Home appliance wiring harness

3C Home appliance wiring harness

Copyright @ 2024 Dongguan Yixian Electronic Technology Co., Ltd. All rights reserved. 粤ICP备17108298号 Sitemap