The principles that should be considered in the design process of automobile wiring harness

As there are more and more electronic control units in the car, the amount of data transmission of each electronic control unit is also increasing by multiple times, which requires the car wiring harness to have better information transmission function, and then leads to the more and more complex design of the car wiring harness. Draw the electrical schematic diagram and circuit diagram of the vehicle; Energy distribution for each electrical subsystem and circuit according to the electrical schematic diagram; Determine the wiring form of the wire harness; Draw 2D wiring harness diagram and 3D wiring harness layout diagram; These wiring harness design steps must be carefully considered. In addition, still have a few wiring harness design principle also should be taken seriously, make every effort car wiring harness design is comprehensive and meticulous, do not give any mistake.

1 wire harness between one or two relatively moving parts must be fixed to each part, and the connection length of the wire harness should be more than 25mm larger than the maximum replacement distance of the two parts.

2. All wiring harnesses arranged near moving parts should have at least 50mm clearance requirements. At the maximum assembly tolerance of the harness, the gap between the harness mounted on the drive train and the parts not mounted on the drive train is at least 19mm. At the maximum assembly tolerance of the harness, this gap is to ensure the full range of motion of the moving part/assembly under other operating conditions.

3. The minimum clearance between the wire harness and the adjacent parts that are not associated with the wire harness is 6mm, unless the wire harness has been fixed to this part, or there is a shield between the wire harness and the nearby moving parts.

4. the need for manual assembly, to press into the seat of the wire harness fasteners, as well as those cable clip inserted holes and slots, should be designed in accordance with the following maximum installation force; The operation force is 45N for finger pressed fixed parts; The operating force is 75N for fixed parts pressed by hand.

5. The car harness branches must have sufficient slack (greater than 25mm in the minimum length of the harness) so that they do not add load to the connected sensor or other.

6. In order to prevent the ground lug from damaging any wiring harness on the trunk, the minimum clearance between the ground lug on the wiring harness trunk and the wiring harness trunk should be maintained at 25mm during loading.

7. In order to ensure the normal function of the relevant rubber plug on the automobile wire harness, the blocked installation hole must meet the relevant requirements.

8. The rubber plug shall be designed to be fully assembled into the sheet metal hole with less than 100N mounting force.

9. The noise generated by the wiring harness to the headrest of the driver's seat should not be greater than 50dB, and the frequency should be 50-15000Hz. The role of automotive wiring harness in the vehicle is to transmit or exchange the power signal or data signal of the electrical system to realize the function and requirements of the electrical system. If the car wiring harness design is not good, can not organically combine the functions of each part, it is possible to make the wiring harness become the car fault multiple links. Therefore, wiring harness designers should carefully carry out every step of the car wiring harness design steps, consider many principles should be paid attention to, to ensure the car wiring harness design is reasonable and reliable.

This article is compiled and published by "Yishen Electronics", if you need to reprint, please indicate the source and source, original address:https://www.yixiandianzi.com/news/152.html

Dongguan Yixian Electronic Technology Co., Ltd.

Tel: +86-0769-82822709

Phone: +86-18819098350/18819095853

E-mail: [email protected]/[email protected]

Address: 301 Room 2 Block No.39 Chuangye Road Mulun Village Changping Town Dongguan City Guangdong

Automotive harness cable glossary

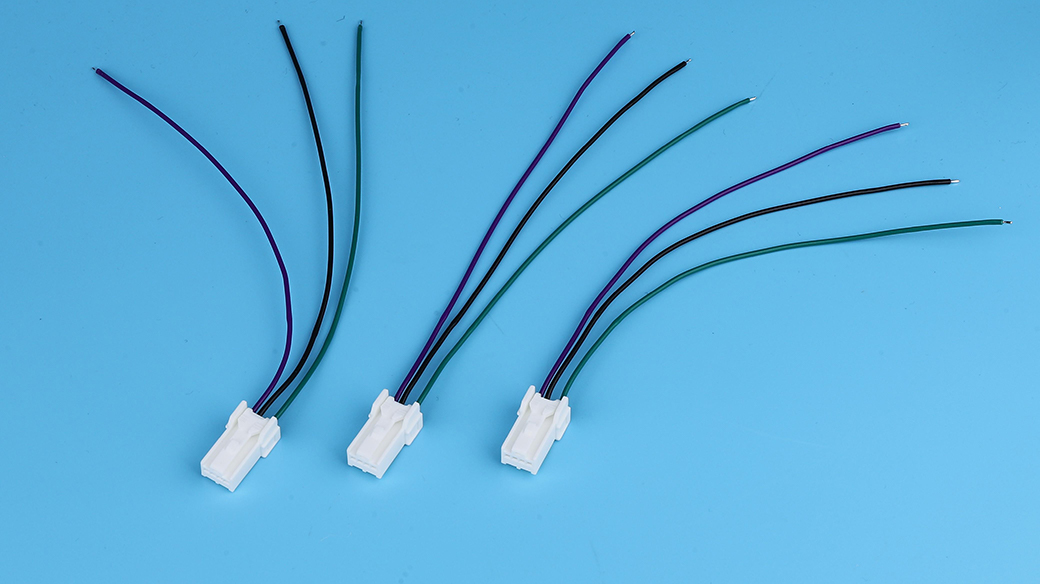

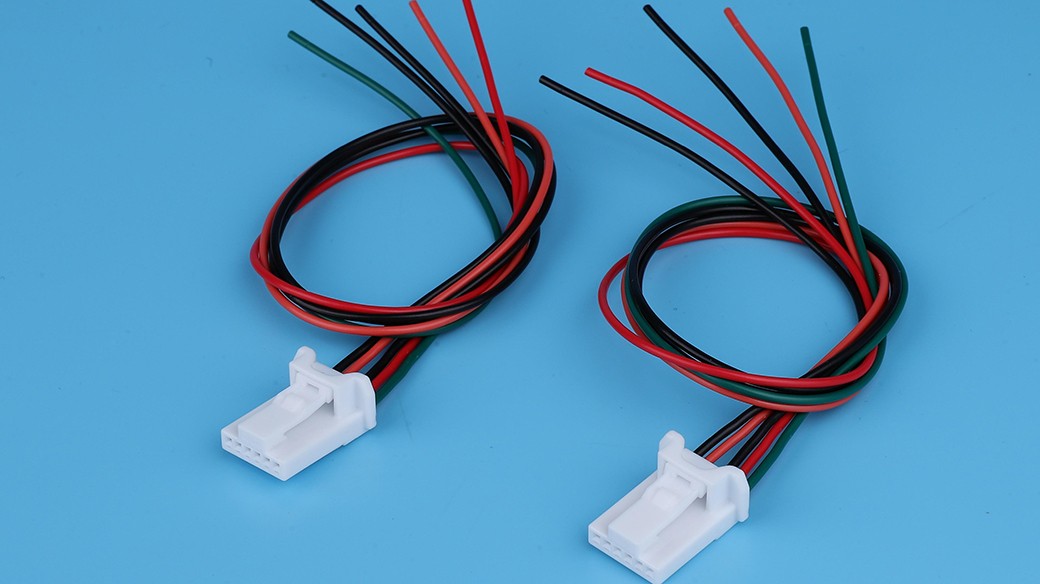

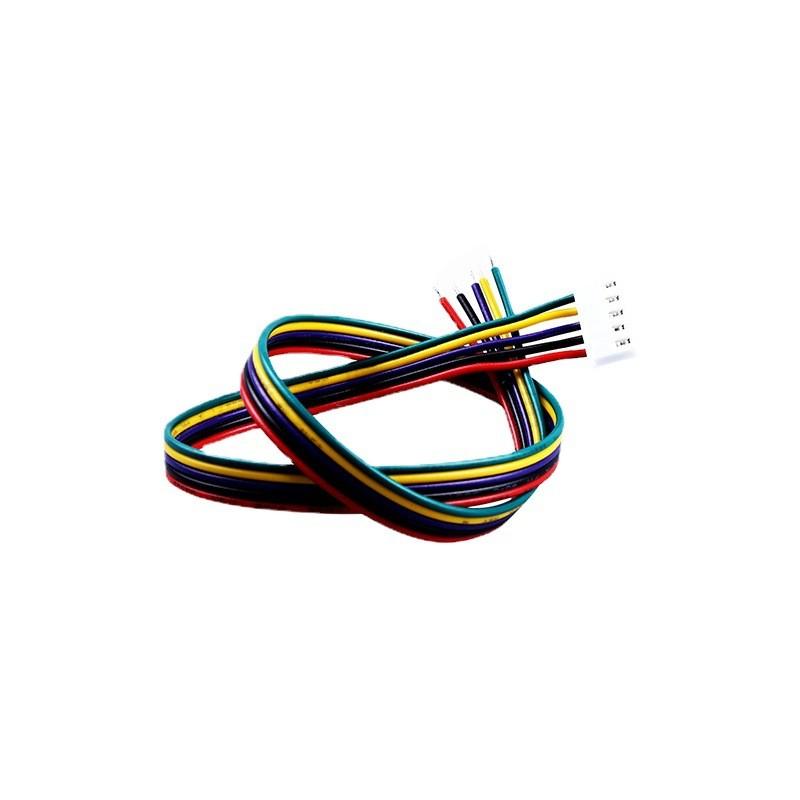

Focus on a variety of custom wire harnesses, electronic wires, terminal wires, wire harnesses, cable...

From the point of view of the use of the terminal, the function that should be achieved is that the ...

Harness key raw material understanding1. Wire cognitionWire defines a wire product used to transmit ...

When the fault of automobile wiring harness can be detected

What are the common problems in wiring harness manufacturing?

Automotive wiring harness

3C Home appliance wiring harness

Flexible Flat Cable

Automotive wiring harness

Flexible Flat Cable

Connectors and terminals

3C Home appliance wiring harness

Connectors and terminals

Copyright @ 2024 Dongguan Yixian Electronic Technology Co., Ltd. All rights reserved. 粤ICP备17108298号 Sitemap