What are the common problems in wiring harness manufacturing?

Wiring harness manufacturing industry is based on the cable/connector/plastic parts and tape these raw materials together, the key technology is peeling and cutting the terminal and then additional welding crimping heat shrink foam and visual detection of this series of processes; The automotive wiring harness designer will use CAN(Controller Area Network-BUS) technology to complete wiring and make drawings according to the electric distribution of the vehicle, including the formal plan and 3D assembly drawings, and then send them to the wiring harness manufacturer, who will then make and confirm the tooling board drawings according to the customer's drawings. Then the factory can start manufacturing;

At present, there are several common problems in the manufacturing process of wiring harnesses inside factories.

1. Inserting the wrong wire means that the wire with the terminal is inserted into the incorrect connector hole. For example, it should be inserted into the No. 1 hole, because the staff mistakenly inserted into the next No. 2 hole, which will lead to no function effect, is a serious mistake;

In general, clear drawings will be posted on the corresponding parts of the tooling board to inform the staff what color wire should be inserted into which hole position, in addition, the staff will not be wrong to compare the safe operation process to work; This kind of mistake is usually due to the need to strengthen training and develop protective measures when new employees are hired and production is accelerated. The last step is an electric measuring platform, so there is no need to worry too much.

2. There are many processes in the factory for connector or fuse box damage. Nodes must be set in advance to monitor and collect data to see which step the error occurs, and then analyze and develop measures; Damage is usually caused by incoming materials and transportation.

3, the connector push lock pull stage, this step is necessary to do, first insert hole push in place, this time will make a crisp sound, then gently pull out, if the wire is not back, it shows that the plug in place and fixed; If this step is not done properly, it will also result in invalidation, so pay special attention to it.

This article is compiled and published by "Yishen Electronics", if you need to reprint, please indicate the source and source, original address:https://www.yixiandianzi.com/news/160.html

Dongguan Yixian Electronic Technology Co., Ltd.

Tel: +86-0769-82822709

Phone: +86-18819098350/18819095853

E-mail: [email protected]/[email protected]

Address: 301 Room 2 Block No.39 Chuangye Road Mulun Village Changping Town Dongguan City Guangdong

What is the reason for the good quality of wiring harness?

What are the common problems in wiring harness manufacturing?

From the point of view of the use of the terminal, the function that should be achieved is that the ...

Electronic wire and terminal cable custom wire harness all kinds of wire and cable, are everywhere i...

The principles that should be considered in the design process of automobile wiring harness

What do you think is the reason for the good quality of wiring harness?

Industrial equipment wiring harness

Medical wring harness

Automotive wiring harness

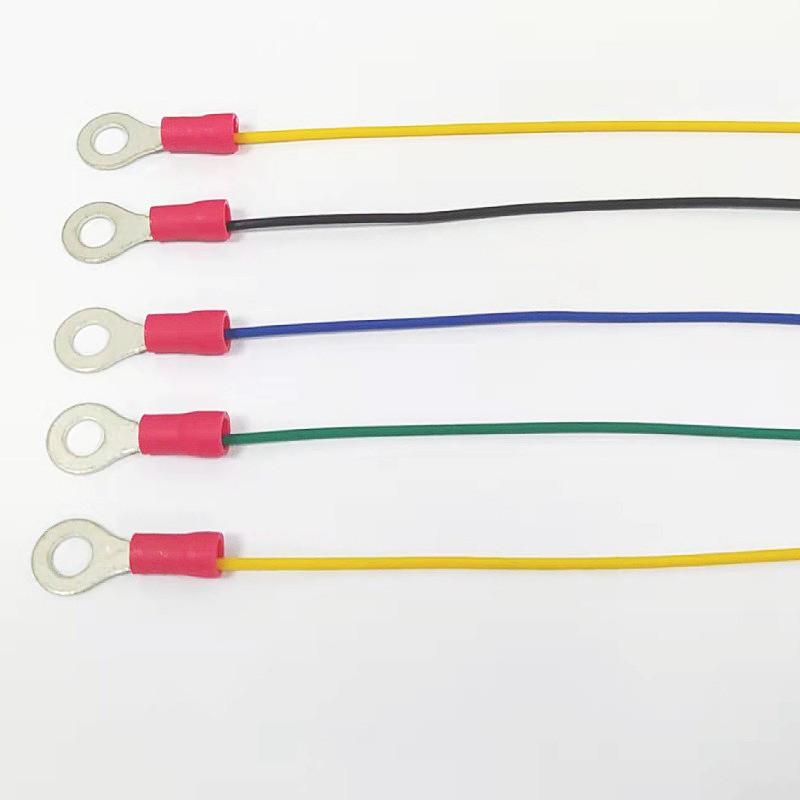

Terminal wring

Terminal wring

Industrial equipment wiring harness

Automotive wiring harness

3C Home appliance wiring harness

Copyright @ 2024 Dongguan Yixian Electronic Technology Co., Ltd. All rights reserved. 粤ICP备17108298号 Sitemap